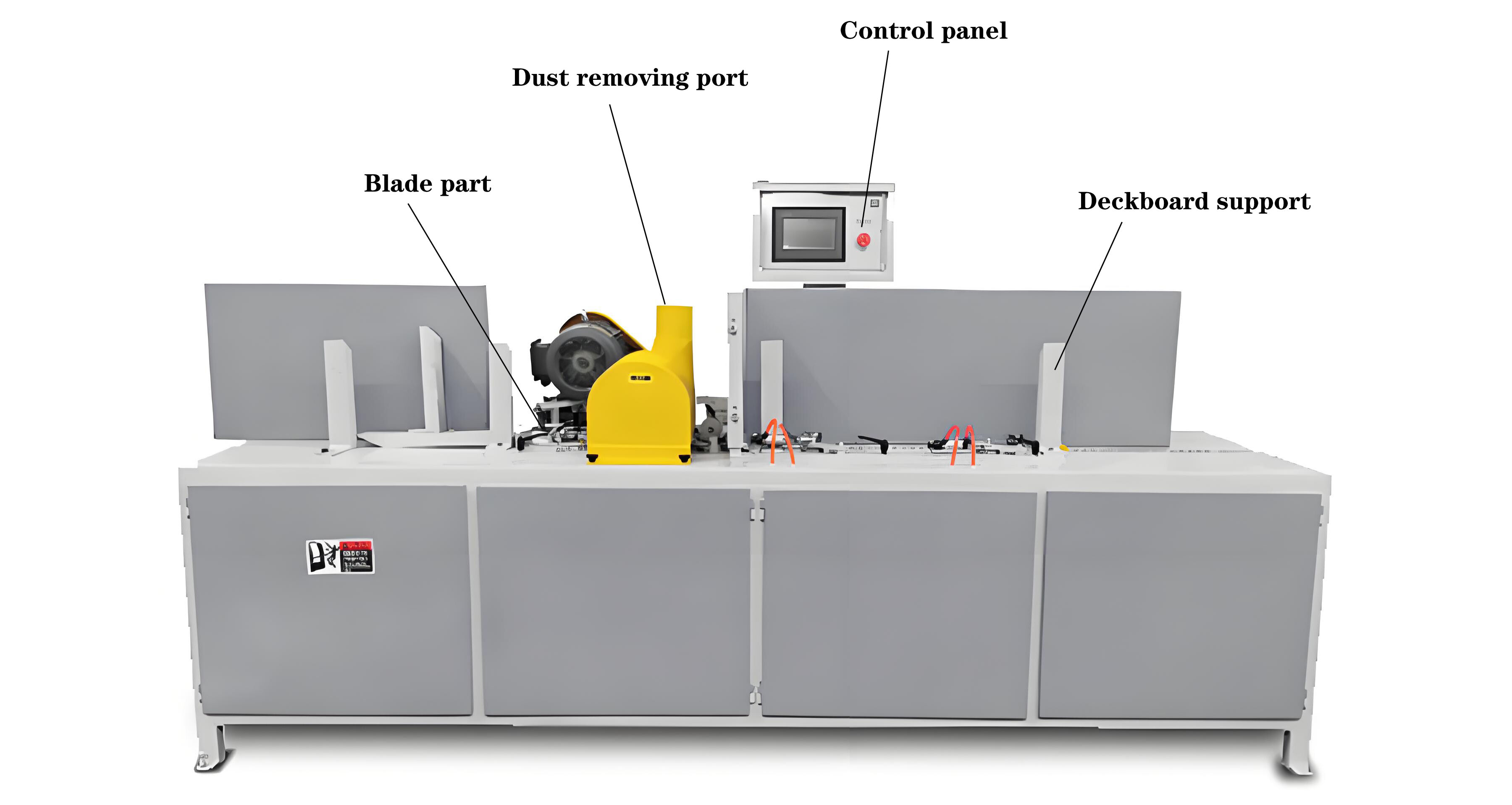

✦The wood pallet edge milling machine also call wood chamfer machine ,it can automatically process and cut pour out the edges and corners for the wooden stringer/wood board, for facilitate the cart and forklift access.

✦It can be continuous feeding, feeding groove can put many wood material at one time. Adopted the progressive motor, the slotting size can be adjusted as requested. High efficiency with 500-700 pcs wood material per hour. The edge of the product section after process would be smooth and neat, uniform specifications.

✦So it is widely used in the industries of wooden pallets, always as the important equipment for the wood pallets production line.

✦Features is Feeding continually , Easy operation with simple design,With high efficiency, can process 400 pcs wood pallet boards per hour.The final products is smooth and regular, Low cost , less manpower .

| Capacity | 600-1500mm |

| Speed | 500-700pcs/hr |

| Cutter style | ≤45°One of each side |

| Power | 4kw |

✦lmported PLC control, to ensure the stable production.

✦ lt is mainly used to pour out the edges and corners of the bottom of the wooden pallet.

✦Easy for the in and out of the forklifts.

✦ Simple operation, one worker is enough..