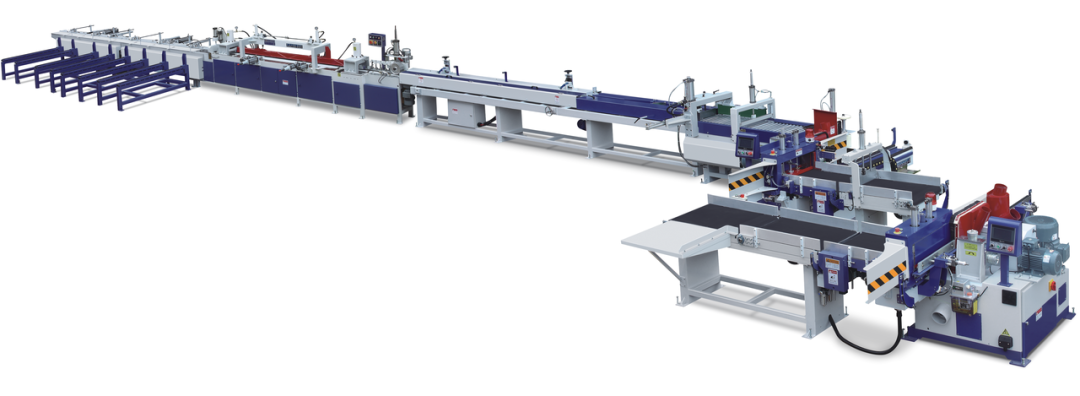

The production line is 20 meters long and 6 meters wide. It consists of 7 parts: automatic combing, automatic gluing, automatic conveying, fully automatic tooth connection, fixed-length sawing, fully intelligent stacking and collecting, and a uniquely designed unloading system that allows forklifts to unload directly. It saves labor and time, improves production efficiency, and can achieve large-scale integrated wood production!

The FJL150-8SS series production line adopts servo drive, and the infinite length gear configuration is fully upgraded, which doubles the work efficiency and realizes full automation production in the factory.

| Model | FJL150-8SS | |

| Machine parameters | Feed length | 150-850mm |

| Comb tooth height | 20-150mm | |

| Maximum processing width of combing machine table | 590mm | |

| Crimp thickness | 20-80mm | |

| Crimp width | 30-150mm | |

| Spindle diameter | Φ50mm | |

| Spindle speed | 5600rpm | |

| Crushing knife shaft diameter | Φ30mm | |

| Crushing knife shaft speed | 2840rpm | |

| Maximum crimping length | 6000mm | |

| Maximum crimping pressure | 7000kg | |

| Motor power | Spindle motor power | 15kw*2 |

| Crushing knife motor power | 4kw*2 | |

| Trimming saw motor power | 0.75kw*3 | |

| Total power of comb conveying motor | 0.75kw*2 | |

| Servo drive motor power | 2kw*2 | |

| Total power of belt conveyor | 1.5kw | |

| Roller conveyor total power | 2.25kw | |

| Chain conveyor total power | 3.75kw | |

| Grafting machine hydraulic system motor power | 5.5kw | |

| Grafting machine saw motor power | 2.2kw | |

| Grafting machine conveying motor total power | 1.1kw*2+0.75kw | |

| Receiver lifting motor power | 0.75kw | |

| Total Power | 64.65kw | |

| Remark | Working air pressure | 6-8Bar |

| Dust suction air volume | 9000m³/h | |

| Installation Dimensions | 24000*6000mm |

Automatic belt conveyor

✦ Belt conveyor automatically conveys wood

✦ Put multiple pieces of wood side by side

✦ Higher efficiency

Smooth cutting

✦ Automatically and quickly align the material, and the end face is cut smoothly

✦ Anti-slip setting to prevent edge collapse

✦ Safe and fast, saving manpower

Servo motor drive, automatic combing

✦ Automatic and fast combing

✦ Precise combing positioning, fast response

✦ Uninterrupted, efficient and reliable

Automatic gluing function

✦ Adopting self-developed gluing system

✦ Synchronizing the feeding speed and the workbench

✦ Able to achieve a higher glue utilization rate

✦ Reduce glue consumption and improve environmental protection

Automatic material turning and conveying

✦ Roller conveying, automatic material turning

✦ Twice as fast as the general speed of peers

Chain conveyor pre-connection

✦ Chain conveyor, large conveying capacity, stable operation

✦ Wear-resistant and corrosion-resistant, no need for manual handling, fast and efficient

Automatic crimping

✦ The pressing system presses materials synchronously in all directions, using a standard large oil cylinder with sufficient pressure to ensure that the wood can reach 100% flatness

Unlimited length sawing

✦ Ensure that the size of each finished wood piece is consistent, the length of the wood can be set arbitrarily, and the wood can be cut automatically at a fixed length

Automatic stacking and material collection

✦ Automatic and fast batch material collection, reducing labor, suitable for large-scale production needs