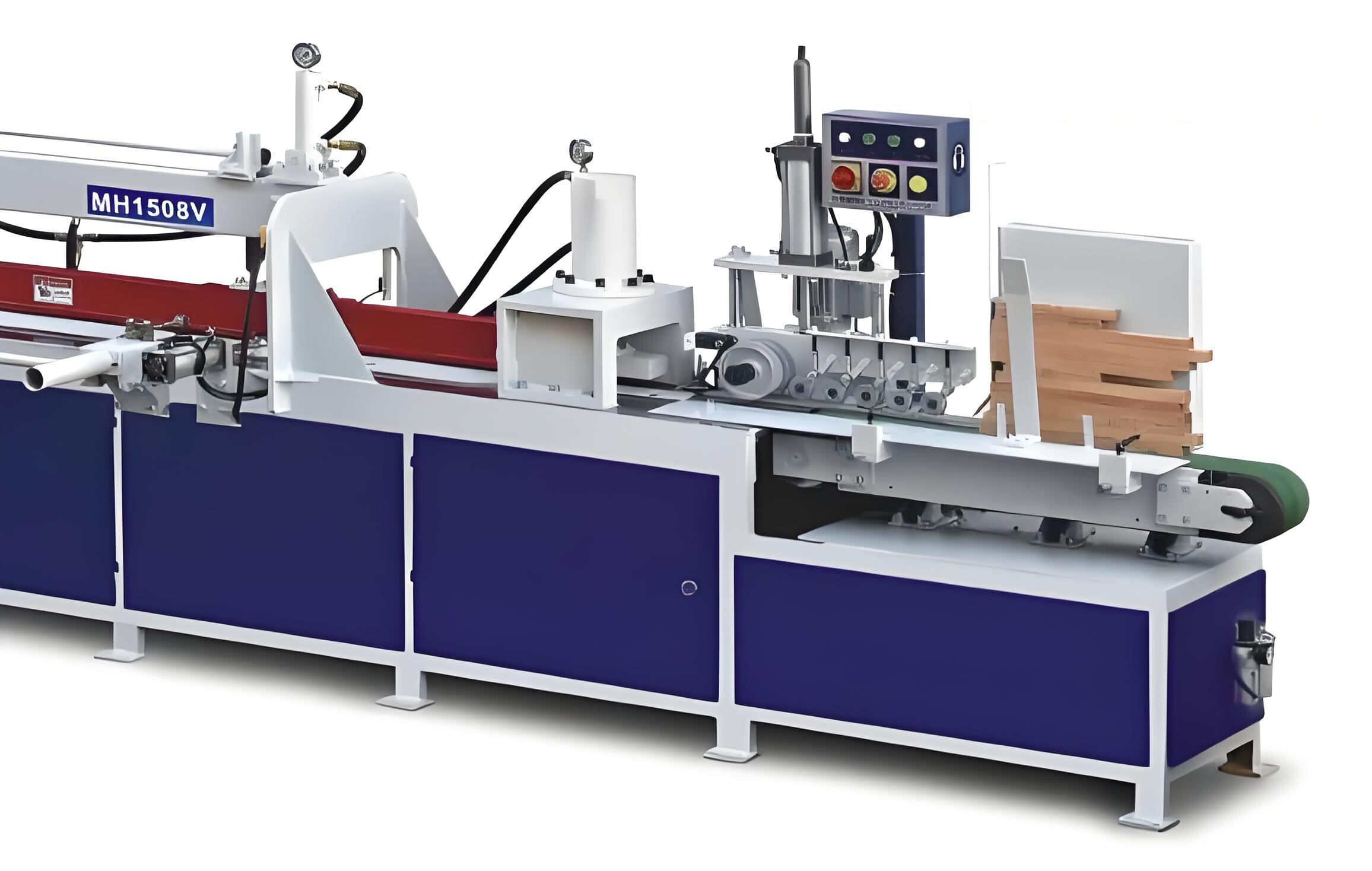

In recent years, the furniture industry has developed rapidly and competition among industry production lines has become increasingly fierce. Comb-tooth wood splicing machines are necessary equipment for solid wood panel companies.

It is also a "sharp blade" for the furniture industry to keep its foothold in the market

Compared with the traditional stand-alone working mode

The FJL150BS-S automatic production line saves time and labor. It uses PLC control, touch screen operation and mechanical transmission to make the entire production line operation simpler. It eliminates the need for intermediate material turnover personnel and manual glue application personnel, reduces the intensity of work operations, saves glue, and can be batched. production, shorten the production cycle, improve the on-time delivery rate of products, and reduce production costs.

| Model | FJL150BS-S | |

| Machine parameters | Comb tooth combination feeding length | 150-850mm |

| Comb height | 20-150mm | |

| Maximum processing width of combing machine table | 590mm/800mm | |

| Spindle diameter | Φ50mm | |

| Spindle speed | 5600rpm | |

| Crushing knife shaft diameter | Φ30mm | |

| Crushing knife shaft speed | 2840rpm | |

| Motor power | Spindle motor power | 15kw*2 |

| Crushing knife motor power | 4kw*2 | |

| Trimming saw motor power | 0.75kw*3 | |

| Total power of comb conveying motor | 0.75kw*2 | |

| Servo drive motor power | 2kw*2 | |

| Total power of belt conveyor | 0.75kw | |

| Roller conveyor total power | 0.75kw | |

| Cutting saw motor power | 2.2kw | |

| Hydraulic system motor power | 5.5kw | |

| Conveying motor power | 1.1kw*2+0.75kw | |

| Total Power | 57.9kw | |

| Remark | Working air pressure | 6-8Bar |

| Dust suction air volume | 9000m³/h | |

| Installation Dimensions | 14000*6000mm |

Feature Highlights

✦ Touch screen operation

The touch screen human-computer interaction control system is simple and convenient to operate, and the response is fast and stable.

✦ High precision workbench

High-precision workbench, fully automatic wood conveying, high efficiency and high precision.

✦ Quickly assemble ingredients

Automatically and quickly collect materials, neatly cut the end face, equipped with anti-slip settings, no edge collapse or material leakage

✦ Servo drive & automatic comb

Servo motor drive, fast running speed, smooth and stable movement, high comb precision

✦ Automatic glue application

Using self-developed glue application reminder, the feed speed is synchronized with the workbench, the effective bonding area is large and the bonding strength is high.

✦ Automatic crimping

All-round hydraulic crimping, automatic feeding, high-speed conveying, and efficient splicing increase the production efficiency by more than 40% compared with similar types of wood splicing machines.

✦ Unlimited length sawing

Automatic sawing of unlimited lengths, suitable for splicing and processing of wood of various sizes. The length is fixed first and then sawed to ensure that the length of the finished wood after tooth splicing is consistent.

✦ Automatic stacking and collecting

Automatically and quickly collect materials in batches, reducing labor and suitable for mass production needs

Important features

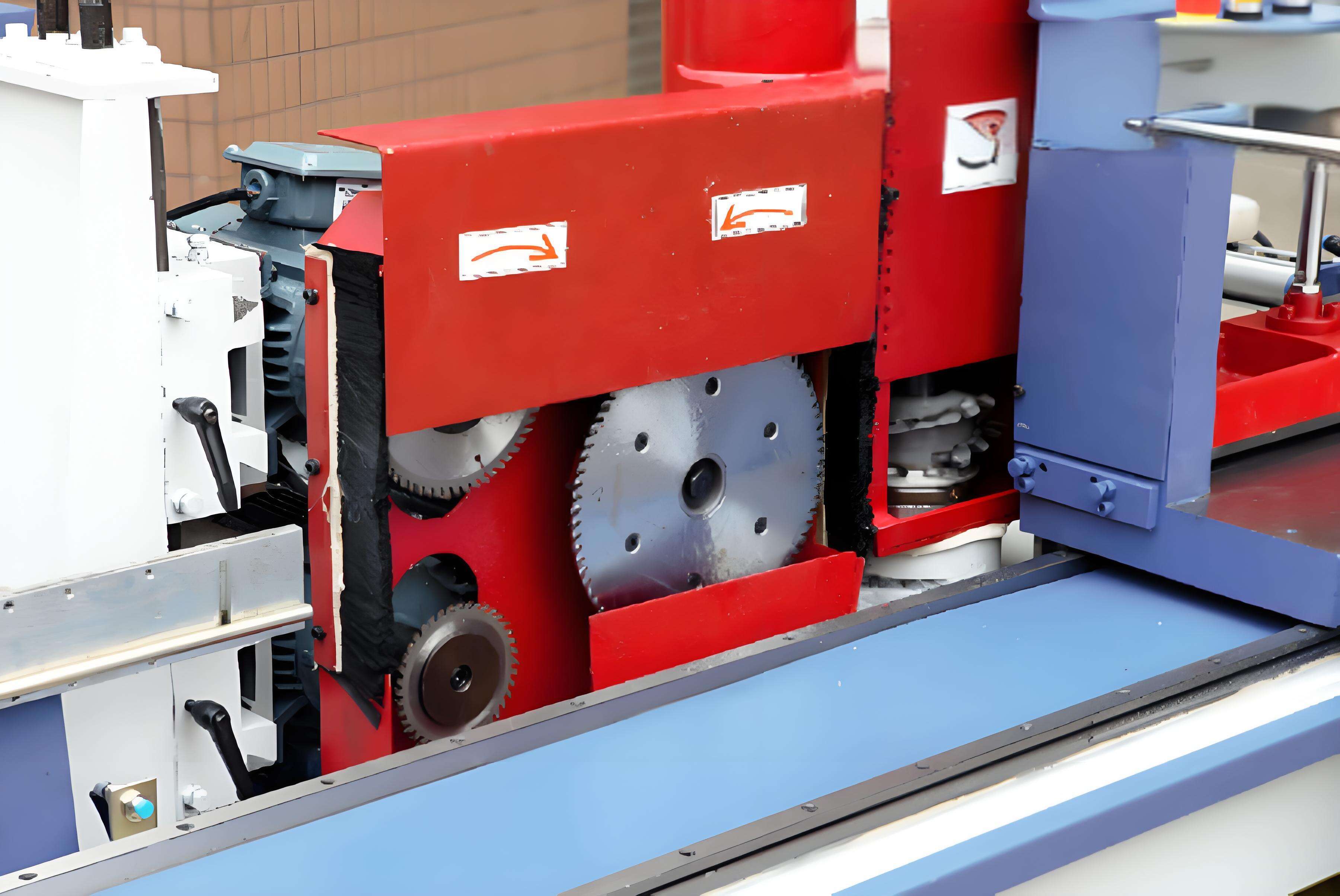

✦ After gathering the materials, crush the wood chips

First, score the lines with a small saw blade, then use a crushing knife to cut the wood neatly, and crush the wood chips for easy vacuuming.

✦ Any fixed length

The length can be arbitrarily determined according to order requirements, and the operation is simple and convenient.

✦ Pressing device

Multiple auxiliary multi-speed elastic pressing devices, flexible rotation, uniform pressing, and increased smoothness of wood tooth joints

✦ Automatic pushing plate

After sawing, the push plate automatically pushes the material, eliminating the need for manual picking, improving efficiency.

✦ Automatic lubrication device

Automatically refuel and lubricate the transmission rails at regular intervals to ensure long-term normal operation of the transmission system.