In recent years, due to the shortage of log resources, the price of raw materials and labor costs have risen, which has directly led to the continuous increase in production costs in the wood processing industry.

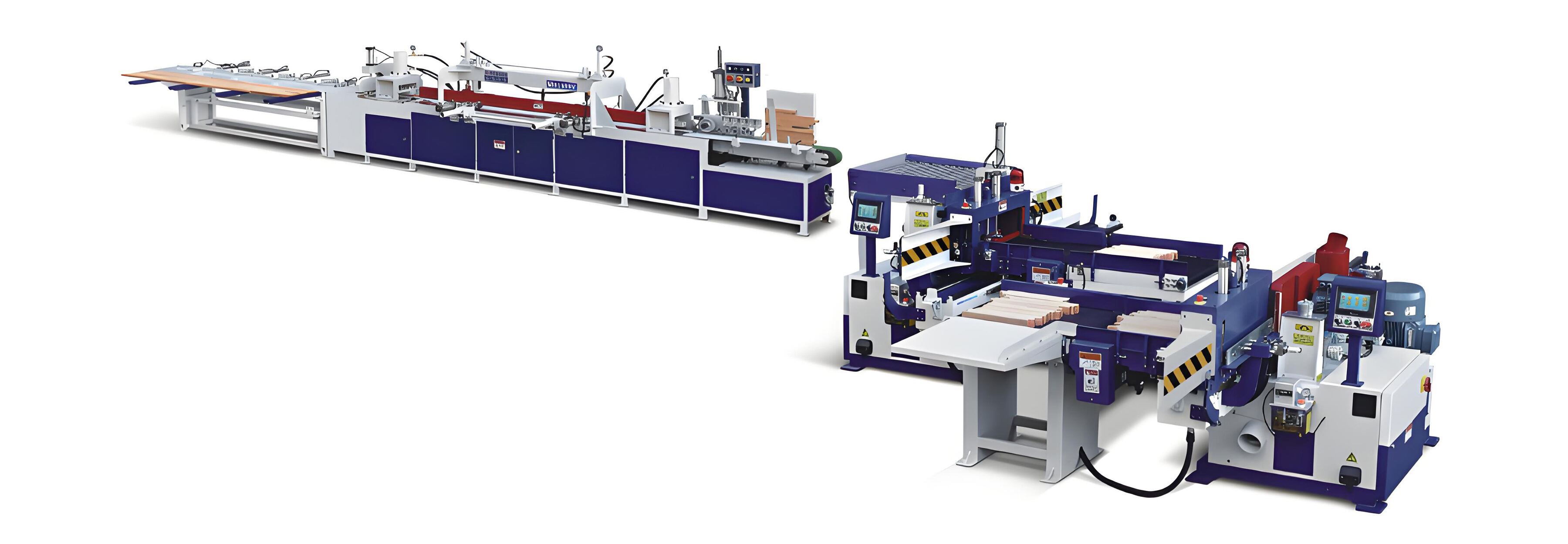

Want to reduce labor expenses and reduce the loss of high-end wood to reduce costs? Recommend this set of automatic infinite length tooth joint production line FJL150BS-V to you. 3 people can operate an entire production line, which is widely used in various wood tooth joint processing.

The FJL150BS-V series production line adopts servo drive, and the infinite length tooth joint configuration is fully upgraded. Replace manual processes with highly integrated automated processing. It can realize automatic, efficient and low-consumption manufacturing processes, shorten the wood processing cycle, improve wood quality, reduce product costs, and save manufacturing resources.

Production and processing flow

✦ Two-stage conveying platform continuous unit feeding horizontal row of a number of direct neat material to promote

✦ Servo configuration, fast response, accurate comb, safe and efficient

✦ The feeding speed of the automatic glue spreading system and the worktable simultaneously improve the utilization ratio of glue

✦ All-round hydraulic gear connection, using standard large cylinder, full pressure in place of wood, can reach 100% smoothness

✦ Automatic fixed-length, sawing can be set to arbitrary, length of wood teeth to end- product wood consistent

✦ Intelligent material pushing, less manual labor.

| Model | FJL150BS-V | |

| Machine parameters | Comb tooth combination feeding length | 150-850mm |

| Comb height | 20-150mm | |

| Maximum processing width of combing machine table | 590mm | |

| Spindle diameter | Φ50mm | |

| Spindle speed | 5600rpm | |

| Crushing knife shaft diameter | Φ30mm | |

| Crushing knife shaft speed | 2840rpm | |

| Motor power | Spindle motor power | 15kw*2 |

| Crushing knife motor power | 4kw*2 | |

| Trimming saw motor power | 0.75kw*3 | |

| Total power of comb conveying motor | 0.75kw*2 | |

| Servo drive motor power | 2kw*2 | |

| Total power of belt conveyor | 0.75kw | |

| Roller conveyor total power | 0.75kw | |

| Cutting saw motor power | 2.2kw | |

| Hydraulic system motor power | 5.5kw | |

| Conveying motor power | 1.1kw*2+0.75kw | |

| Total Power | 57.9kw | |

| Remark | Working air pressure | 6-8Bar |

| Dust suction air volume | 9000m³/h | |

| Installation Dimensions | 14000*6000mm |

Production and processing flow

✦ Automatic material conveying

The belt conveyor automatically conveys and can continuously process and convey wood, and the material is directly pushed on the conveyor table.

✦ Servo configuration, automatic and fast combing

Adopt servo motor drive, fast response, accurate combing, anti-slip setting, prevent edge collapse, and neat end cutting

✦ Automatic gluing system

Adopt automatic research and development gluing system, the feeding speed is synchronized with the workbench, the effective gluing area is large, and the gluing strength is high

✦ Automatic crimping

Automatic feeding, all-round hydraulic crimping, wood can reach 100% flatness

✦ Unlimited length sawing

Automatically sawing materials without limit of length, the length of the wood can be set arbitrarily to ensure the same length of the finished products.

✦ Automatic material pushing

Automatic material pushing saves manpower and improves productivity