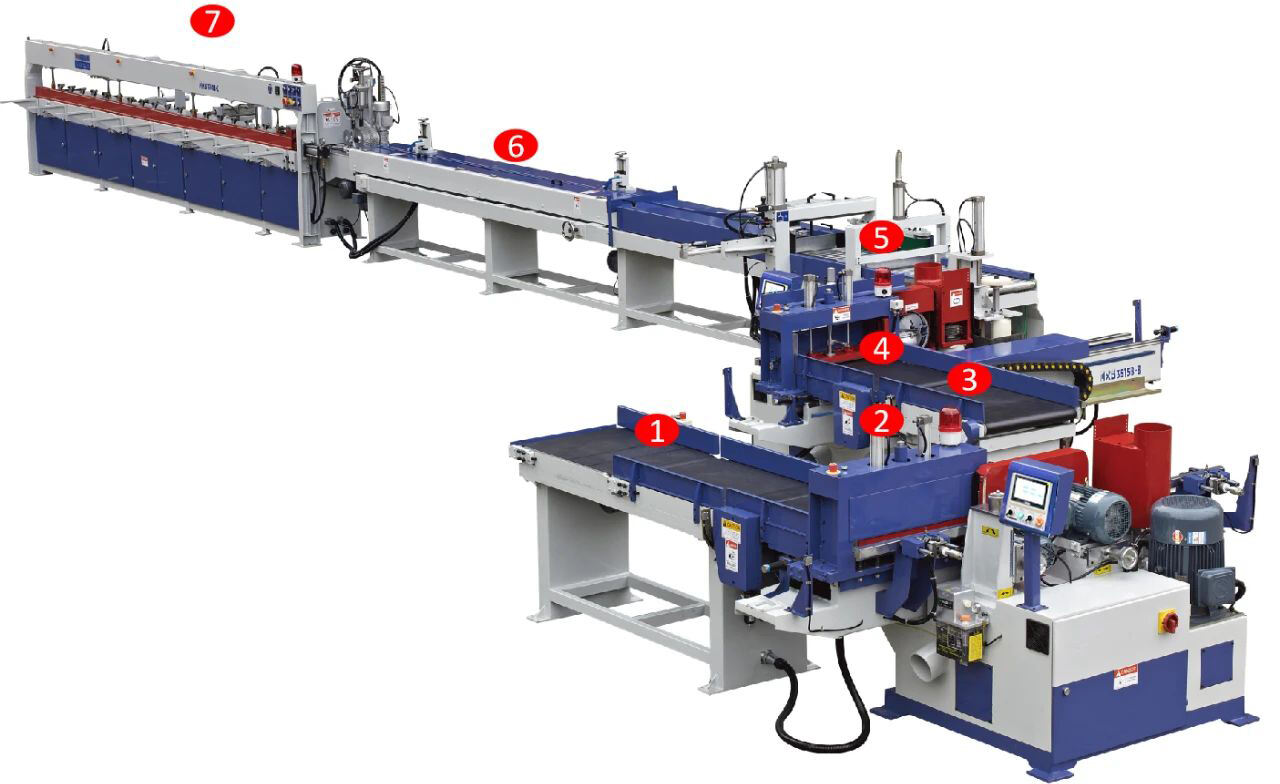

The first problem of the toothed plate industry is how to efficiently batch toothed joints. The processing process is complicated and cumbersome, time-consuming and labor-intensive, and the production efficiency is low. However, Shengong Machinery's fully automatic toothed joint production line FJL150-8DS brings high-speed and precise processing for plate toothed joints, and escorts the production efficiency of the furniture industry.

FJL150-8DS adopts a double-station wood jointing design, which can realize automatic conveying → automatic feeding → automatic gluing → docking and forming → automatic discharging at the same time, without manual material collection. High efficiency and labor saving. Moreover, the spliced plates have less deformation in subsequent processing, and their performance is better than ordinary plates. It truly realizes the production line of toothed plates, which is intelligent and efficient, saving time, labor and labor.

| Model | FJL150-8DS | |

| Machine parameters | Feed length | 150-850mm |

| Comb tooth height | 20-150mm | |

| Maximum processing width of combing machine table | 590mm | |

| Crimp thickness | 20-80mm | |

| Crimp width | 30-150mm | |

| Spindle diameter | Φ50mm | |

| Spindle speed | 5600rpm | |

| Crushing knife shaft diameter | Φ30mm | |

| Crushing knife shaft speed | 2840rpm | |

| Maximum crimping length | 6040mm | |

| Maximum crimping pressure | 7500kg | |

| Motor power | Spindle motor power | 15kw*2 |

| Crushing knife motor power | 5.5kw*2 | |

| Trimming saw motor power | 0.75kw*3 | |

| Total power of comb conveying motor | 0.75kw*4+1.8kw*2 | |

| Total power of hydraulic system motor of grafting machine | 3.75kw | |

| Total power of saw motor of grafting machine | 4kw | |

| Grafting machine conveying motor total power | 2.2kw | |

| Total power of belt conveyor | 1.5kw | |

| Roller conveyor total power | 2.25kw | |

| Chain conveyor total power | 3.75kw | |

| Total Power | 67.3kw | |

| Remark | Working air pressure | 6-8Bar |

| Dust suction air volume | 9000m³/h | |

| Installation Dimensions | 18900*6000mm |

Touch screen control, simple and convenient

✦ Simple touch screen operation

✦ No high-end operation requirements for staff

Imported electrical components, brand guaranteed

✦ Using German electrical control components

✦ Ensure fast operation and long-term stability

Microcomputer control, simple and safe

✦ The whole machine PLC microcomputer control system is simple and easy to operate!

✦ Humanized operation function, stable and reliable! Strong safety in use!

Technological innovation, wide range of applications

✦ Through multiple technological innovations, it is suitable for wood with various levels of humidity and hardness.

Automatic protection sensor

✦ Add automatic protection sensor system

✦ Safer operation

Multi-directional sensing, stable performance

✦ High-precision process connection and multi-directional sensing feedback are more stable during operation, greatly improving its stability performance compared to traditional gear connection technology

Equipment advantages

Belt conveyor

✦ Dual-stage conveying work platform, batch feeding, saving human resources and higher efficiency

Quick material alignment

✦ Directly align the material on the conveying workbench, and then perform end sawing and combing after aligning the material.

Fully automatic combing machine

✦ Servo motor driven, precise positioning. The depth and number of teeth of the comb can be adjusted to increase the production efficiency by more than 25% compared with ordinary motor driven.

Automatic gluing

✦ Automatic gluing system, the feed speed is synchronized with the workbench, no need for manual gluing, saving time and labor

Chain conveyor

✦ Turn the glued wood 90°, with fast turning speed and quick storage and pre-connection

✦ Adopt stable chain conveyor configuration to ensure stable and smooth wood conveying.

Automatic crimping

✦ Dual-station continuous crimping, capable of splicing in sections with fixed length