✦ Main Features; Main spindles Double Suport,stable and large drivingforce, fast procesing and increase eficiency. Elegantdesign and functional. Electicaly adjust processing heigh, savingtime and labor. Each day(8 hours) customer can process can process more than 50 m3 according to the working size.

|

Serial NO. / Model |

MJF142S-1750 |

|

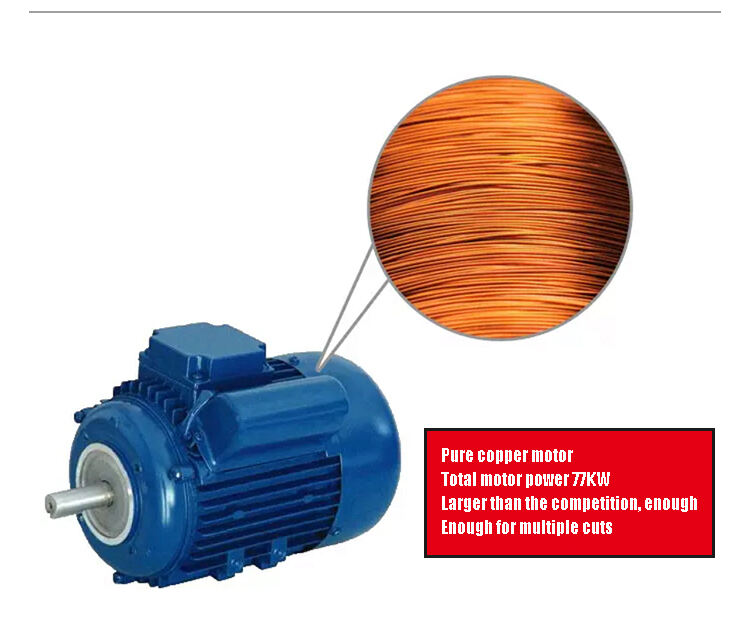

Machine total power |

77KW |

|

Voltage / Frequency |

3HP-380V, 50HZ |

|

Feeding speed |

0-23m/min |

|

Processing length |

≥1500mm |

|

Processing width |

≤500mm |

|

Processing height |

20-170mm |

|

Appearance size (LxWxH) |

2850 x 2040 x 1650mm (without feeding table) |

|

Product weight |

3150kg |

|

Blade Size |

Φ300 x Φ70 |

|

Spacer Size |

Φ120 x Φ70 |

|

Extra Wood Conveyor |

Standard, Can removable |

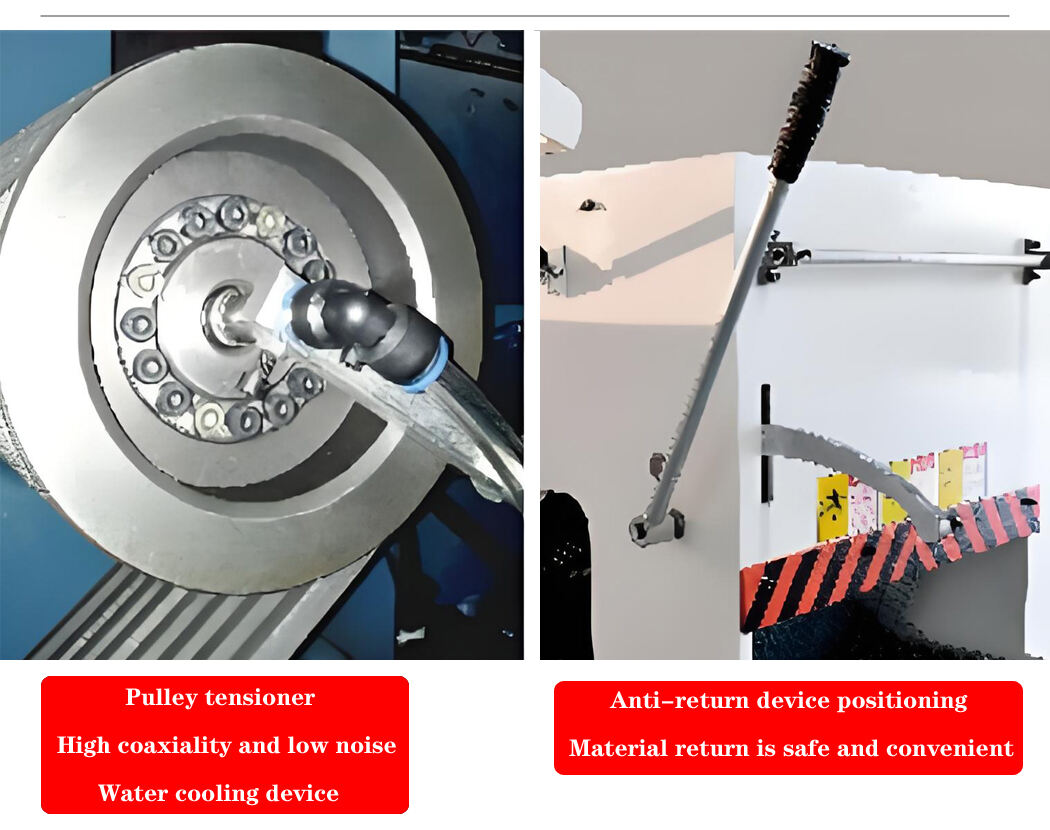

✦ This machine has high production efficiency, high stability, simple operation and maintenance, and high finish of the material. And so on.This equipment is specially designed for wooden house and anticorrosive wood processing. It is suitable for cutting thick timber and large-scale production. The feeding table of the machine can custom-made according to the customer's needs.

✦ The multi rip saw is mainly used for sawing square timber wood into a plurality of square bars. The upper and lower shafts are designed for large diameters. It has the characteristics of small sawing path, smooth sawing surface and high yield. It is an ideal woodworking machinery for processing finger joints, joinery boards and packaging boards.

✦ The thickness of the board can be controlled . It can process a variety of hard logs such as poplar, pine, eucalyptus, fir and green steel.

✦ Especially suitable for sheet metal processing with two planes up and down

✦ Especially suitable for wooden houses and preservative wood processing

✦ It is suitable for processing wooden squares with smaller thickness and cutting them into specification boards

✦ Suitable for large-scale production, high efficiency