When it comes to woodworking and industrial applications, Shengong offers advanced cutting solutions, including multi rip saws and band saws. While both types of saws are designed for precision cutting, they serve distinct purposes and offer different functionalities. Understanding these differences is essential for selecting the right equipment for specific needs.

Multi Rip Saws: Efficient and High-Speed Cutting

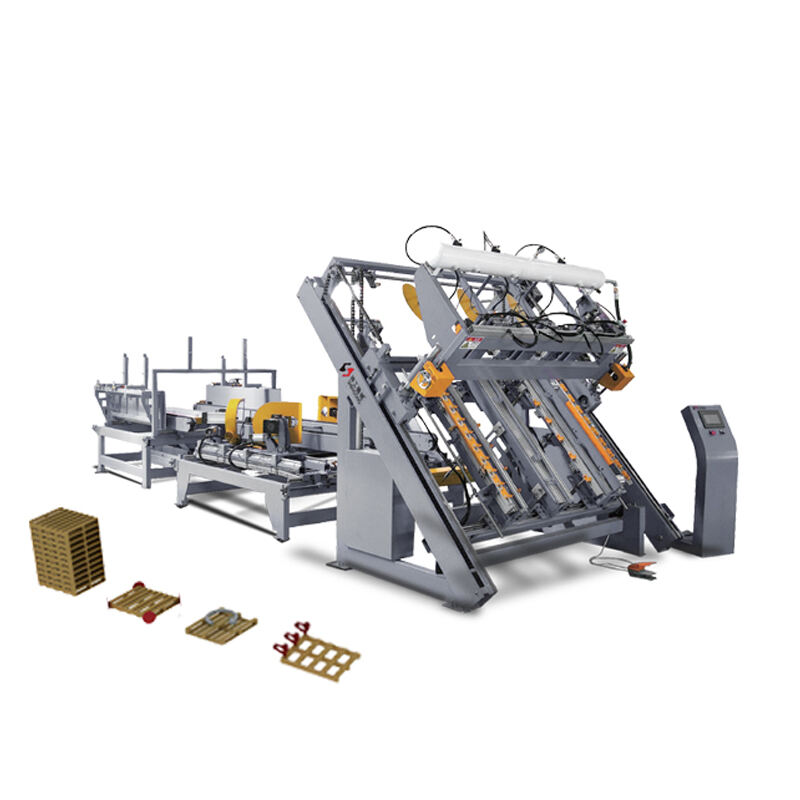

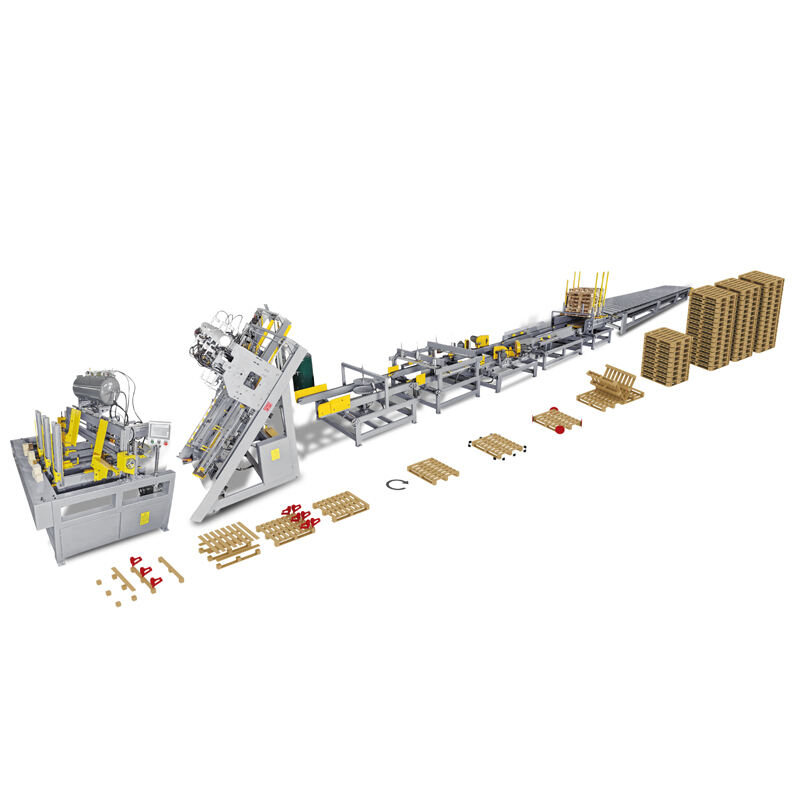

A multi rip saw is a specialized machine used primarily for cutting large panels or timber into narrower strips in a single pass. These saws feature multiple blades that allow for simultaneous cutting, making them ideal for high-speed, high-volume production. Shengong multi rip saws are known for their precision and durability, capable of handling various materials such as hardwood, softwood, and composite boards. The ability to adjust the spacing between the blades allows for flexible cutting options, enabling manufacturers to customize the width of the strips according to their needs.

The key advantages of multi rip saws include their speed, accuracy, and efficiency in mass production environments. However, they are best suited for straight cuts and are less versatile when it comes to intricate or curved cuts.

Band Saws: Versatile and Precision-Cutting

On the other hand, band saws are designed for more versatile and intricate cutting applications. Unlike multi rip saws, which excel in making straight cuts, band saws use a continuous loop of a toothed blade to make both straight and curved cuts with high precision. Shengong band saws are known for their ability to cut through various materials, including wood, metal, plastic, and even non-ferrous metals, making them suitable for a wide range of applications beyond just woodworking.

Band saws are particularly valuable for tasks that require flexibility, such as cutting irregular shapes, curves, or detailed contours. They offer a smoother finish and greater precision, making them ideal for industries that demand high-quality craftsmanship. However, their cutting speed is generally slower than that of multi rip saws, making them more suitable for smaller production runs or detailed work.

Key Factors in Choosing Between Multi Rip Saws and Band Saws

When deciding between a multi rip saw and a band saw, several factors should be considered:

1. Production Volume: If you are working in a high-volume production environment where speed and efficiency are key, a multi rip saw would be the better option.

2. Cutting Precision: For detailed, curved, or irregular cuts, a band saw offers superior precision and flexibility.

3. Material Type: While both saws can handle wood, band saws offer more versatility for cutting other materials like metal and plastic.

4. Cutting Speed: Multi rip saws are faster for cutting large, straight pieces, whereas band saws may take more time for detailed work but provide cleaner cuts.

Both Shengong multi rip saws and band saws have unique strengths that cater to different cutting requirements. The choice between these two tools depends on the type of work you are doing, the materials you are cutting, and your production needs. Understanding the functionality and capabilities of each saw will help ensure you select the best equipment for your projects, leading to improved efficiency, precision, and overall output.